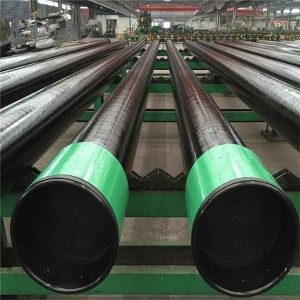

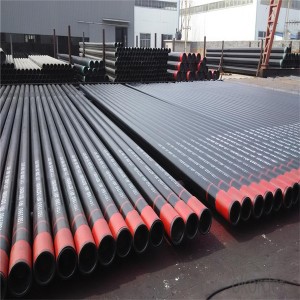

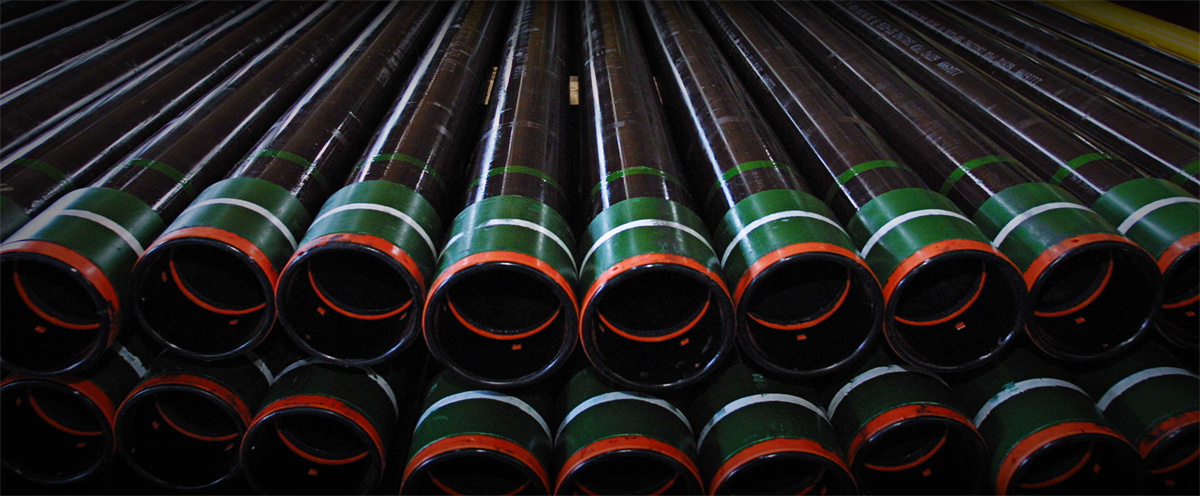

J55 K55 N80 Minyak Tubing jeung Casing Steel Pipe

Casing minyak mangrupikeun pipa baja anu dianggo pikeun ngadukung témbok sumur minyak sareng gas pikeun mastikeun operasi normal sadaya sumur minyak saatos prosés pangeboran sareng parantosan. Unggal sumur ngagunakeun sababaraha lapisan casing nurutkeun pangeboran jero béda jeung kaayaan géologis. Cementing semén dipaké sanggeus casing ieu lowered kana sumur. Beda sareng pipa minyak sareng pipa bor, éta henteu tiasa dianggo deui sareng mangrupikeun bahan anu tiasa dianggo sakali. Ku alatan éta, konsumsi casing akun pikeun leuwih ti 70% sadaya pipa sumur minyak.

| Label | D Luar diaméterna mm | Ketebalan témbok t mm | C Jenis tungtung-finish | |||||||||

| 1 | 2 | |||||||||||

| T&C NU | EU T&C | IJ | ||||||||||

| H40 | J55 | L80 | N80 1Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.9 | 2.75 | 2.9 | 2.76 | 48.26 | 3.68 | PNUI | PNUI | PNUI | PNUI | PNUI | PNUI | - |

| 1.9 | 3.65 | 3.73 | - | 48.26 | 5.08 | PU | PU | PU | PU | PU | PU | PU |

| 1.9 | 4.42 | - | - | 48.26 | 6.35 | - | - | P | - | P | P | - |

| 2 3/8 | 4 | - | - | 60.32 | 4.24 | PU | PN | PN | PN | PN | PN | - |

| 2 3/8 | 4.6 | 4.7 | - | 60.32 | 4.83 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2 3/8 | 5.8 | 5.95 | - | 60.32 | 6.45 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 3/8 | 6.6 | - | - | 60.32 | 7.49 | - | - | P | - | P | P | - |

| 2 3/8 | 7.35 | 7.45 | - | 60.32 | 8.53 | - | - | PU | - | PU | PU | - |

| 2 7/8 | 6.4 | 6.5 | - | 73.02 | 5.51 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 7.8 | 7.9 | - | 73.02 | 7.01 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 8.6 | 8.7 | - | 73.02 | 7.82 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 9.35 | 9.45 | - | 73.02 | 8.64 | - | - | PU | - | PU | PU | - |

| 2 7/8 | 10.5 | - | - | 73.02 | 9.96 | - | - | P | - | P | P | - |

| 3 1/2 | 7.7 | - | - | 88.9 | 5.49 | PN | PN | PN | PN | PN | PN | - |

| 3 1/2 | 9.2 | 9.3 | - | 88.9 | 6.45 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 3 1/2 | 10.2 | - | - | 88.9 | 7.34 | PN | PN | PN | PN | PN | PN | - |

| 3 1/2 | 12.7 | 12.95 | - | 88.9 | 9.52 | - | - | PNU | PNU | PNU | PNU | PNU |

| 3 1/2 | 14.3 | - | - | 88.9 | 10.92 | - | - | P | - | P | P | - |

| 3 1/2 | 15.5 | - | - | 88.9 | 12.09 | - | - | P | - | P | P | - |

| 4 | 9.5 | - | - | 101.6 | 5.74 | PN | PN | PN | PN | PN | PN | - |

| 4 | 10.7 | 11 | - | 101.6 | 6.65 | PU | PU | PU | PU | PU | PU | - |

| 4 | 13.2 | - | - | 101.6 | 8.38 | - | - | P | - | P | P | - |

| 4 | 16.1 | - | - | 101.6 | 10.54 | - | - | P | - | P | P | - |

| 4 1/2 | 12.6 | 12.75 | - | 114.3 | 6.88 | PNU | PNU | PNU | PNU | PNU | PNU | - |

| 4 1/2 | 15.2 | - | - | 114.3 | 8.56 | - | - | P | - | P | P | - |

| Grup | Kelas | Tipe | Total elongation handapeun beban% | kakuatan ngahasilkeun Mpa | Kakuatan tensile min MPa | Teuas max | ||

| min | max | HRC | HBW | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 1 | J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | |

| 2 | L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | |

| L80 | 13Kr | 0.5 | 552 | 655 | 655 | 23 | 241 | |

| C90 | 1?2 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - | |

| T95 | 1?2 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| 4 | Q125 | Sadayana | 0.65 | 862 | 1034 | 931 | - | - |

Inspeksi visual pikeun permukaan pipa

Pariksa dimensi

Uji mékanis dina kakuatan tensile, kakuatan ngahasilkeun sareng elongasi

Analisis kimiawi

Uji NDT kalebet partikel Magnétik, Uji Ultrasonik, Uji Hidrostatik

Tés dampak Charpy

Tés flattening

Uji karasa

Tes drift

Parios tungtung benang nganggo gauge benang sareng cek kopling

J55 sareng K55 mangrupikeun bahan anu sami dina komposisi kimia sareng sipat mékanis, khususna J55 ngagaduhan syarat tegangan minimum anu langkung handap sareng elongasi anu langkung handap, spésifikasi sanésna sami sapertos metode perlakuan panas, uji NDE, uji Charpy Dampak, uji hidrostatik.

J55 / K55 kakuatan ngahasilkeun minimum: 379-552 Mpa;

J55 kakuatan tensile minimum: 517 Mpa, elongation ≥ 19%;

K55 kakuatan tensile minimum: 655 Mpa, elongation ≥ 15%.